summary:

The HYF type fluoroplastic alloy submersible pump is a new type of pump jointly developed, researched and produced by our factory and Shenyang Pump Research Institute. The overcurrent part of the medium is entirely made of fluoroplastic reinforced alloy compression processing, which combines the advantages of various fluoroplastics, has strong corrosion resistance, and has the advantages of non aging and non-toxic decomposition, absolutely eliminating the phenomena of running, emitting, leaking, and dripping. Through the use of nearly a thousand users nationwide, it has been proven that this pump has the advantages of reasonable design, compact structure, stable operation, reliable performance, and easy maintenance. It can transport all corrosive media such as acids, alkalis, oxidants, etc. from -85 to 120 ℃ with users. It is the most ideal chemical pump of the 1990s.

2、 Structure

The HYF type fluoroplastic alloy submersible pump is a single-stage single suction vertical pump. The main components include the motor, motor bracket, bearing bracket, base plate, intermediate connecting pipe, pump shaft, impeller, pump body, outlet pipe, etc. The bearing is a rolling bearing lubricated with grease. Users only need to select the pump with the corresponding insertion depth according to the process, directly insert it into the liquid tank, connect the power supply, and operate it in the specified direction (do not reverse).

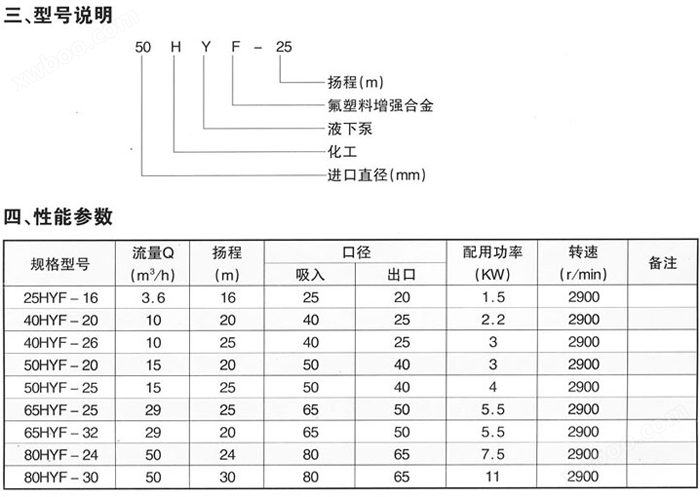

The meaning and performance diagram of the model: